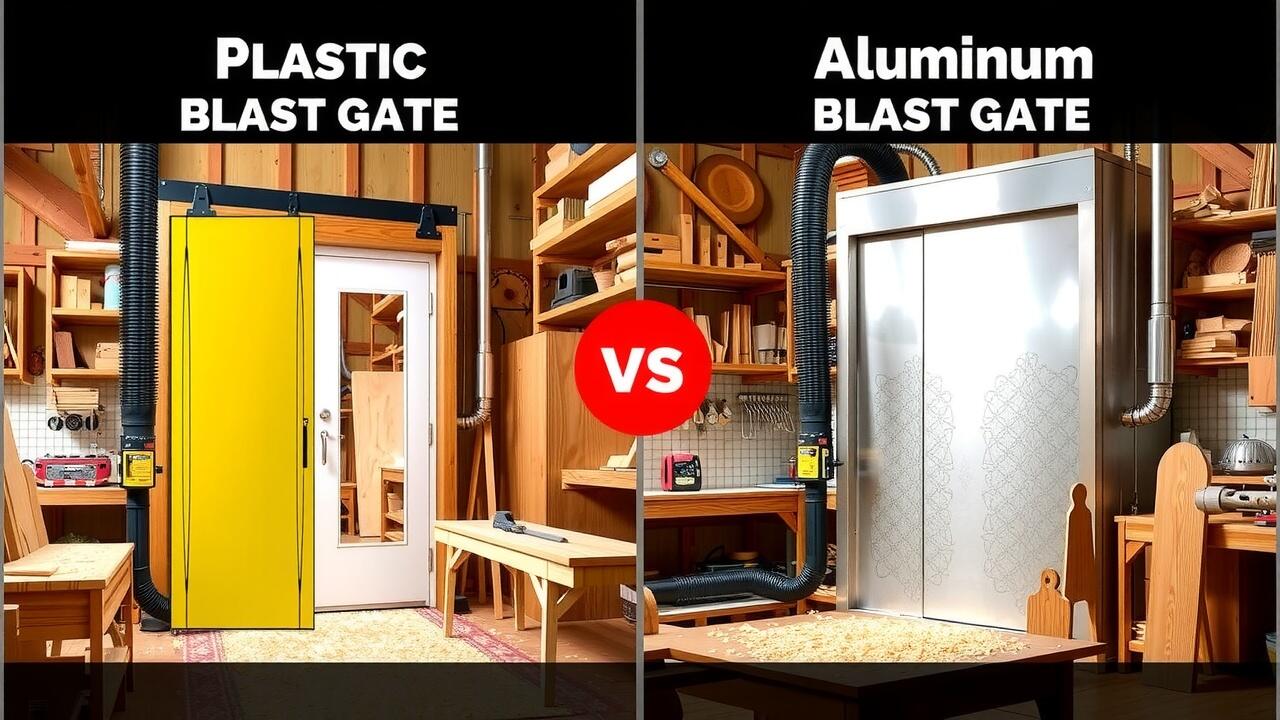

Comparative Analysis of Plastic vs. Aluminum Blast Gate Performance in Woodshops

Key Takeaways

- Methods for Setting Up Plastic and Aluminum Gates

- Sound Emissions Produced by blast gates

- User Interaction and Usability

- Five Essential Tips for Selecting the Ideal Blast Gate

Installation Processes for Plastic and Aluminum Gates

The installation process for plastic blast gates typically involves a straightforward approach due to their lightweight nature. Users can generally secure these gates using screws or adhesive methods, allowing for flexibility in placement. Often, instructions provided with the product outline the necessary steps, making it easier for woodworkers, regardless of experience level. Careful alignment with ductwork ensures an effective fit and optimal performance.

In contrast, aluminum blast gates require a bit more precision during installation due to their heavier construction. Many practitioners opt for a flange connection to maintain strength and ensure airtight seals. The added weight of aluminum necessitates securing the gate more firmly, which might involve using washers or bolts to prevent any accidental displacement during operation. This attention to detail can enhance the durability and longevity of the installation, particularly in high-use environments.

Step-by-Step Guide to Installing Your Blast Gate

Begin by gathering the necessary tools and materials. For most installations, you will need a tape measure, a saw, screws, and a screwdriver. Make sure the area around the dust collection system is clean and unobstructed. This preparation lays the foundation for a smooth installation process. Measure the diameter of the ductwork where the blast gate will be installed. Cut the duct to size if needed, ensuring smooth edges to avoid any air leaks.

Next, position the blast gate between the two sections of ductwork. Align it properly so that airflow is unobstructed when the gate is open. Secure the gate in place using screws to fasten it to the ductwork. It’s essential to double-check that the gate operates smoothly without any binding. Once installed, test the system by turning it on and observing the performance to confirm everything is functioning correctly.

Noise Levels Generated by Blast Gates

The performance of blast gates in woodshops can significantly affect the overall noise levels. Plastic blast gates tend to create less noise compared to their aluminum counterparts. This difference is largely due to the material properties of plastic, which naturally dampen sound vibrations more effectively. On the other hand, aluminum blast gates can amplify noise due to their rigid structure, leading to a louder environment during operation.

Managing the noise generated by blast gates is essential for maintaining a comfortable workspace. Adding insulation around the blast gate area can help reduce sound transmission. Additionally, ensuring proper installation can minimize vibration and rattling, which contribute to unwanted noise. Users should consider not only the function of the blast gate but also its impact on their working conditions.

How Can You Minimize Noise in Your Workspace?

Reducing noise levels in a woodworking shop involves a combination of equipment choice and strategic placement. Utilizing materials that absorb sound can significantly lower the overall noise level. Carpeting or rubber mats can be placed on the floor, while sound-absorbing panels can be added to walls. Ensuring that machines are well-maintained also plays a vital role. Worn bearings or misaligned parts can increase vibrations and noise.

Choosing quieter tools and machinery can contribute to a more peaceful workspace. Selecting blast gates designed with noise reduction features is another effective measure. Some manufacturers list decibel ratings for their products, which can aid in making informed choices. Additionally, establishing designated operational hours may minimize noise disturbances for others in proximity, creating a more pleasant environment overall.

User Experience and Practicality

When evaluating the practicality of plastic and aluminum blast gates, ease of use plays a crucial role for woodworkers. Plastic gates typically feature a lightweight design that makes them easy to manipulate, even for those working in tight spaces. Their smooth operation often leads to quicker adjustments during woodworking tasks. In contrast, aluminum gates may be heavier but are known for their durability and strength, which can instill confidence during rigorous usage.

The aesthetic aspect also influences user experience. Plastic blast gates often come in various colors and finishes, allowing for customization to match workshop decor. On the other hand, aluminum gates present a more industrial look, appealing to those who prefer a rugged aesthetic. Both types can provide efficient airflow regulation; however, the choice may ultimately depend on individual preferences for functionality and design in a busy workshop environment.

Which Type of Blast Gate is Easier to Operate?

When evaluating ease of operation, plastic blast gates often stand out due to their lightweight nature. Users find that the low weight makes them easier to manipulate, especially in tight spaces where quick adjustments are necessary. Additionally, plastic gates typically feature a simpler design, which can contribute to a more straightforward user experience. The simplicity of operation is beneficial for hobbyists and professionals alike, allowing for seamless integration into the workflow.

On the other hand, aluminum blast gates come with their own advantages. Their durability means that even though they may be heavier, the investment often leads to prolonged performance. Some users appreciate the sturdiness that aluminum gates offer, as they can withstand aggressive handling and endure extreme conditions. Furthermore, the precision in the construction of aluminum gates often results in smoother operation, reducing friction and providing an effortless sliding mechanism.

5 Key Strategies for Choosing the Right Blast Gate

Choosing the right blast gate involves assessing various factors that align with your specific woodshop needs. Begin by evaluating the material composition. Plastic gates are typically lighter and more affordable, while aluminum options often offer greater durability and corrosion resistance. Consider your shop's environment, especially if moisture is a concern.

Next, take into account the size and airflow requirements. Ensure that the diameter of the blast gate fits the dust collection system to maintain optimal airflow and efficiency. The ease of operation is also critical; look for designs that allow for smooth adjustments. Durability is essential. Select gates built to withstand regular use without compromising performance over time.

Factors to Consider Before Making a Purchase

When evaluating different blast gates, the material plays a significant role in performance and durability. Plastic options tend to be lighter and often more affordable, making them appealing for smaller shops or hobbyists. Aluminum gates, however, offer increased durability and resistance to wear, making them a suitable choice for environments where heavy usage is anticipated. It's essential to assess the specific needs of your woodshop and consider how each material aligns with your operating conditions.

The size and design of the blast gate are critical factors that can affect airflow and efficiency in your dust collection system. Measure the ductwork and ensure compatibility with the gate's dimensions. Additionally, consider the mechanism for operation; some gates feature levers or handles that are easier to use than others. A gate that aligns well with your existing setup will enhance both usability and effectiveness, which is vital for maintaining a clean and safe workspace.

Conclusion

A comprehensive examination of plastic and aluminum blast gates reveals notable differences in their installation processes, noise levels, and overall user experience. While both materials come with their unique advantages and disadvantages, the choice ultimately depends on the specific needs of the woodshop environment. Users may prefer aluminum for its durability or plastic for its lightweight nature and cost-effectiveness.

Selecting the right blast gate involves evaluating several factors, including installation ease, noise reduction capabilities, and operability. By considering these elements, woodworkers can make an informed decision that enhances both performance and efficiency in their workshops.